Technologies For Design

MECHANICAL DESIGN STUDIO

WHO ARE WE

TECHNOLOGIES FOR DESIGN - MOLDOVA is a mechanical design studio created in 2017, being a subsidiary of the Italian studio in Turin, which works in the field of mechanical engineering and robotics for over forty years. Our goal is to provide complete technical assistance for the construction of robotic systems and special assembly and processing equipment. The subsidiary from Moldova allows us to offer economically competitive services, without prejudice to the high level of quality. All our designers have been trained by highly qualified Italian designers.

Our customers are:

• COMAU S.p.A.

• ALENIA S.p.A.

• IVECO – CNH S.p.A.

• THYSSENKRUPP S.p.A.

• SATIZ S.p.A.

• MICHELIN S.p.A.

• SEA MARCONI S.p.A.

FACTS AND FIGURES

Customers

Projects

Support hours

Engineers

SERVICES

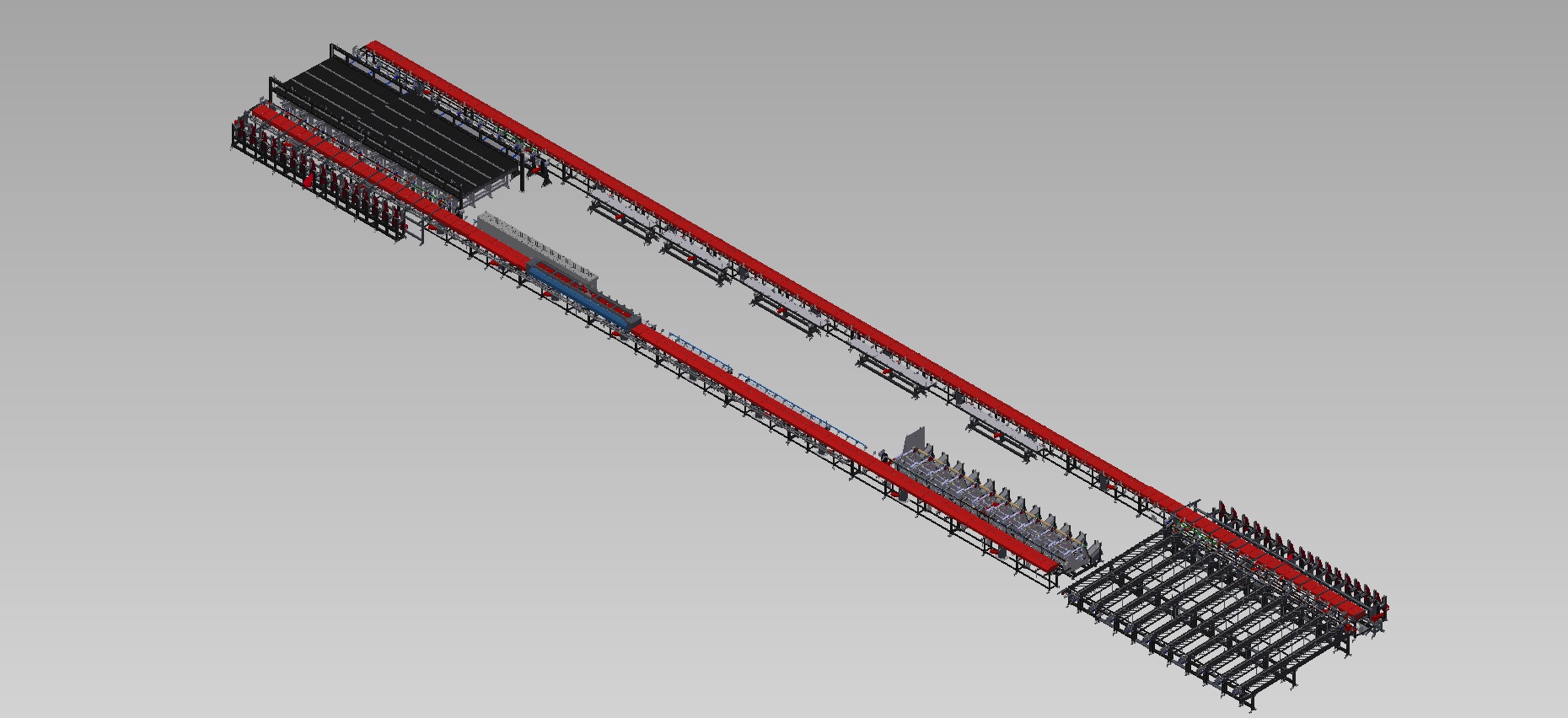

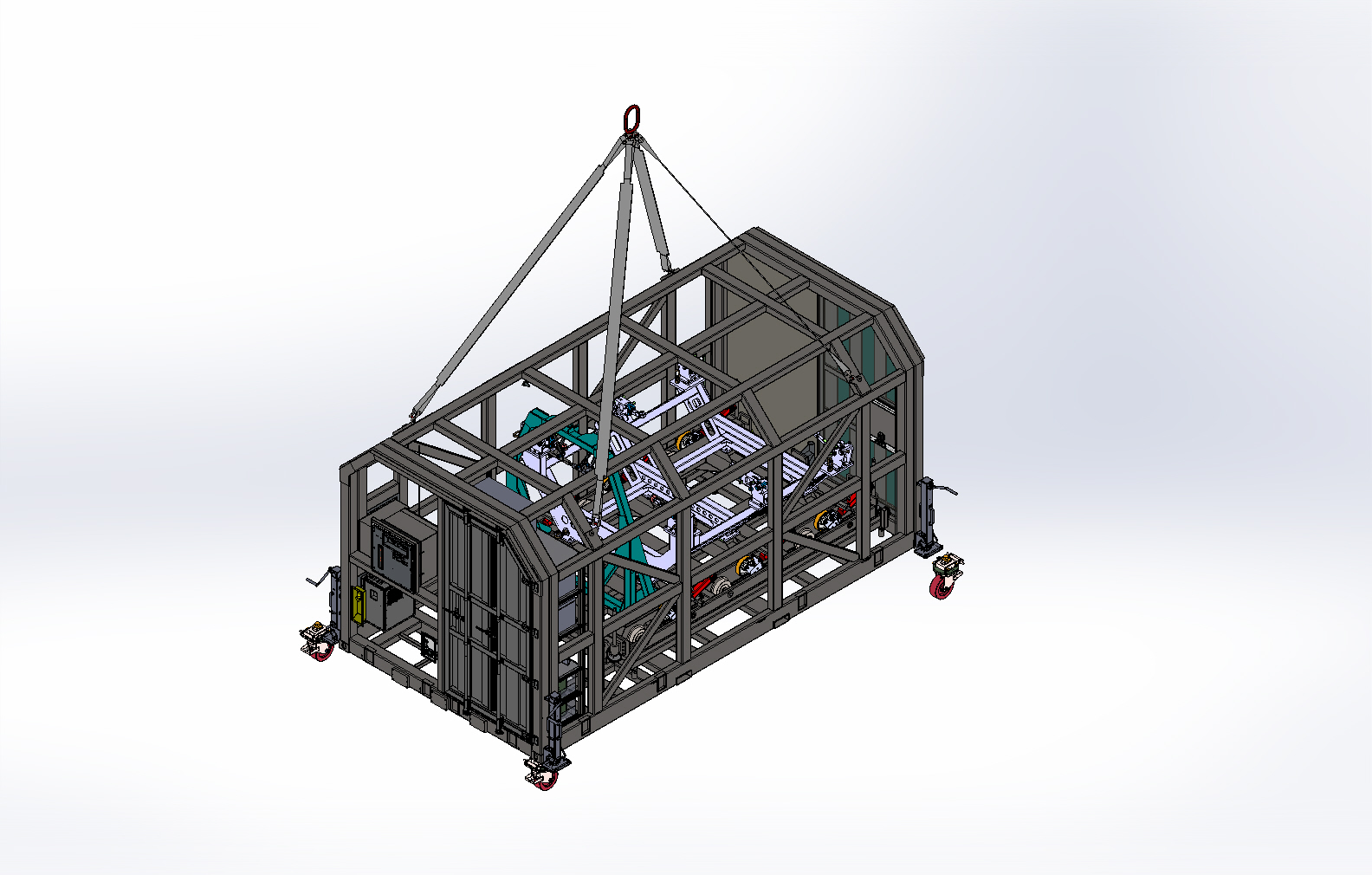

INDUSTRIAL LOCATION

Arrangement of equipment and production lines in the production area determines the industrial structure. Designing a new equipment or production system may require changing the existing location or, in some cases, creating a new location in order to optimize the production line. Changes in the operational location or the introduction of a new equipment or department are typical examples in which the analysis of the arrangement becomes fundamental.

• DEVELOPMENT Physical arrangement of the equipment.

• DESIGN Also, for existing equipment, readjustment for new needs.

• REVISIONS and checks of existing equipment that must be done safely.

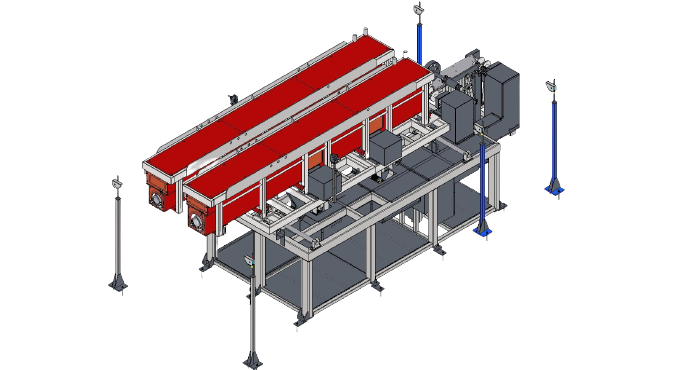

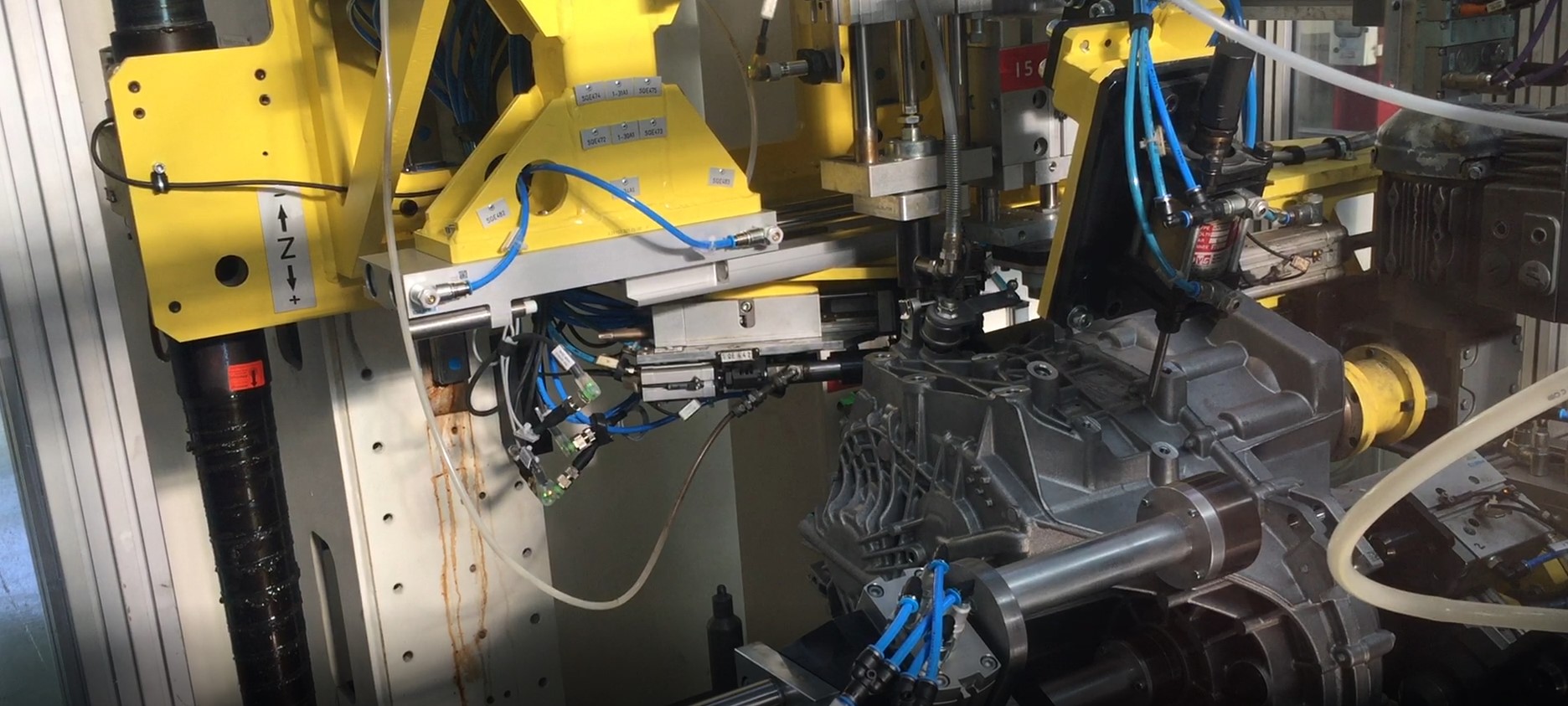

3D MODELING

TFD has the ability to design industrial machinery and equipment following the specific needs of the customer due to the knowledge and feasibility of planning, 3D modeling and subsequent verification of the projects themselves. Starting from a verbal idea or a simple CAD project, our studio can provide a real picture of what the final version will look like thanks to the use of 3D modeling. This thing considerably reduces both execution time and costs. 3D allows a wide range optimization for the execution of layouts (constructive-assembly-bending), CAD files for numerical control machines, exploded views, lists, manuals, time studies and production methods.

• ANALYSIS Feasibility studies, analyzes developed with the customer's technical department.

• LOCATION DESIGN Complete study of the customer's production needs.

• CHECKING THE POSSIBILITY OF IMPLEMENTATION Analysis and suggestion of possible specific solutions to achieve the objective.

• DESIGN AND ACHIEVEMENT Initiation of the construction process with various previously acquired information.

From the point of view of carpentry and metal mechanics, TFD is able to offer its customers a 360-degree service: from detailed design of individual components to complete study of complex assemblies. Based on the decisions taken with the customer in the initial phase, it exists the possibility to create a three-dimensional model of the product, which allows the establishment and eventual elimination of deficiencies or problems, as well as the continuous verification of the conformity of the designed product with the initial specifications. Once it has been established that the three-dimensional model meets the established requirements, it is possible to continue with the completion of the 3D model with the detailed design of the product. Subsequently, we proceed to the construction of the constructive layouts, the list of materials and all the necessary documents.

CONSTRUCTIVE LAYOUTS

One of the objectives of TFD, which has been strengthened over the years, is to produce complete construction layouts with drawings that are easy to interpret and decode, so that the production and assembly of the product at the location to be as efficient as possible. To achieve this best, our designers make very detailed drawings. A complete detailed table simplifies the production and assembly of equipment by providing all the information. Layouts are usually provided in 2D and may be the subject of exclusive activities for existing projects upon request.

• SIMPLICITY Simple layouts for decoding.

• DETAILS Detailed layouts for an efficient construction of the project.

DESIGN OF SHEET-METAL PARTS

The design of sheet-metal parts requires the use of specific CAD tools, which manipulate the geometry in a two-dimensional manner, leaving the program to control the radius of curvature, cuts, bends and calculations of sheet evolution. TECHNOLOGIES FOR DESIGN, has managed over the years and projects to perfect the design of open sheets, using special bends for the bending machine of each customer, minimizing the imperfections of the couplings. There are provided the detailed bending layouts, list of materials and all the appropriate cutting geometries for laser positioning.

• EXPERIENCE Since the eighties, experience in the field of metal sheets.

• DETAILED LAYOUTS Detailed layouts for folds, with all the useful geometries for cutting.

METAL CARPENTRY

TECHNOLOGIES FOR DESIGN has an excellent experience in designing metal carpentry units by separating individual parts, such as:

• Unique individual layouts

• Layouts for folds

• Constructive layouts for assembly

• Geometries for laser cutting

• Tracing

• Production lists

• Material purchase lists

Due to the experience gained in the last years in the field of light and heavy carpentry, TFD is better able to guide the customer during the design process. EXPERIENCE Since the eighties, experience in the field of metal sheets. DETAILED LAYOUTS Detailed layouts for folds, with all the useful geometries for cutting.

REVERSE ENGINEERING

Starting from an existing object, we get the project for the following objects. This is the reverse engineering process. It can be useful if You want to improve individual components or even whole machinery (equipment). In principle, the purpose of the improvements could be to reduce costs or improve operational efficiency.

CONVERSION FROM 2D TO 3D

Transition from paper to digital design or from 2D to 3D is becoming a reality that companies, for different needs, will specifically appeal to. Projects archiving is always an essential necessity for every company, taking into account any maintenance and / or modifications. However, the considerable volume of paper involved in some projects indicates that conversion will be increasingly in demand. Our studio has been offering for years to its clients this transposition service with the greatest accuracy of paper archives, which are often very large.

• ACCURACY We reduce time and costs by using the best software at the moment.

• FILES We offer all useful project files to the customer in the new 3D formats.

Converting 2D projects to 3D projects is becoming an increasingly common necessity. This conversion requires a high technical level, and companies are not always able to meet this type of need. It is therefore more profitable to entrust in many cases the transfer of old projects to an external entity, such as TFD, which, due to its specific and consolidated experience, is able to perform this procedure efficiently both economically and in terms of terms, as well as with high reliability.

3D EXPLODED IMAGES

3D exploded images, both static and dynamic, are an added value for both manuals and spare parts management, facilitating reordering without interrupting the production chain. In the 3D exploded images, the individual components can be viewed separately, which allows the visualization of their correct positioning during assembly, simultaneously facilitating the work of technicians, with the consistent optimization of times and minimizing the margins of error.

• • ANALYSIS Feasibility studies, analyzes developed with the customer's technical department.

• LOCATION DESIGN Complete study of the customer's production needs.

• CHECKING THE POSSIBILITY OF IMPLEMENTATION Analysis and suggestion of possible specific solutions to achieve the objective.

• DESIGN AND REALIZATION Initiation of the construction process with various previously acquired information.

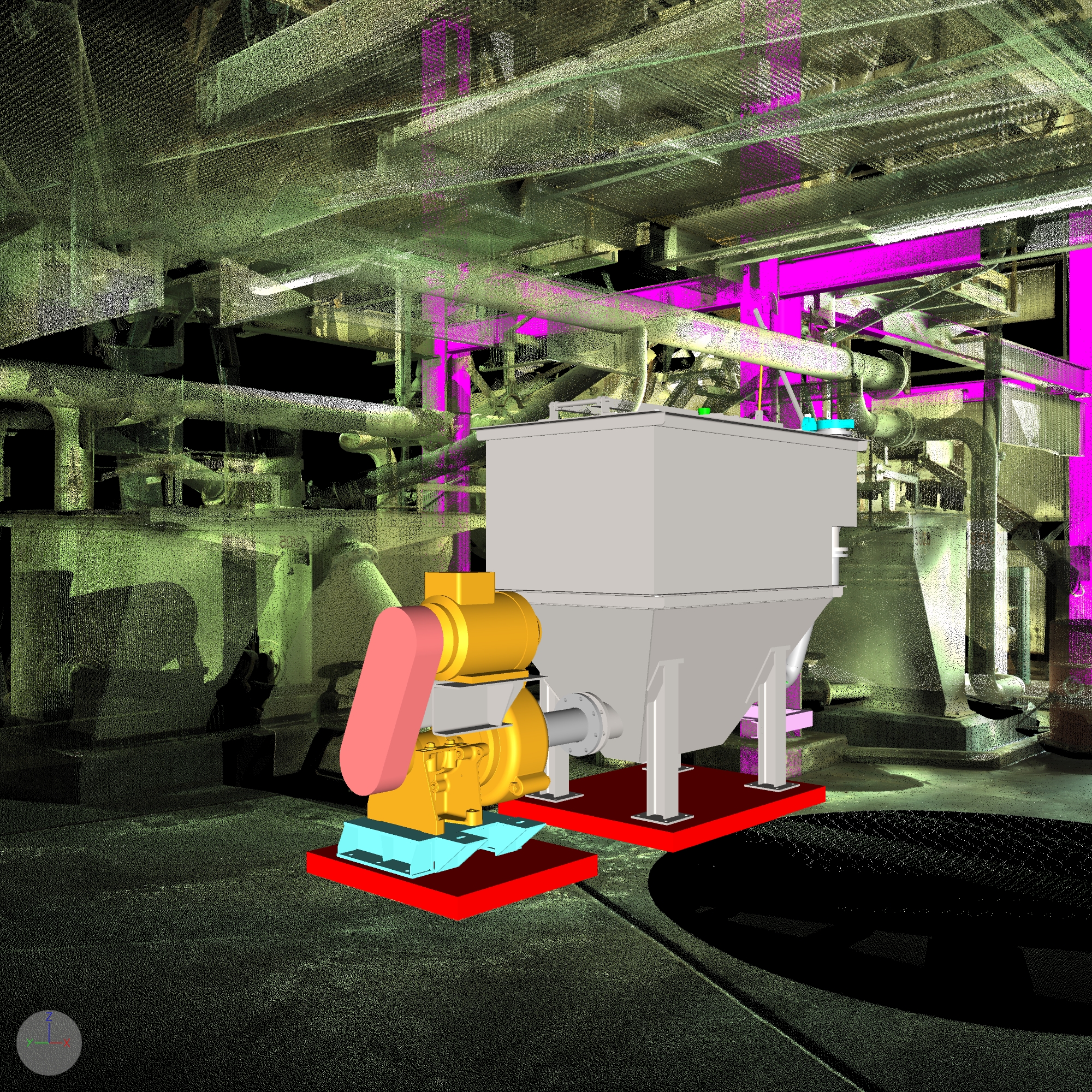

LASER SCANNER 3D

We are equipped with a Leica ScanStation Laser Scanner that allows you to perform three-dimensional scans on a spherical cap of 360 ° on the Y axis and 270 ° on the X axis. This makes it possible to generate a perfectly measurable point cloud combined with high-resolution images. resolution.

• WHAT IT CAN DO Through 3D scans we are able to offer: - three-dimensional surveys that can be measured by the customer at any time on a free internet platform; - two-dimensional plans at any height of buildings / departments in the industrial and civil areas; - three-dimensional simulations of industrial lay-out with insertion of 3D models of the new machines / lines to be installed; - analysis of interference generated by the insertion of new plants in existing industrial environments; - transformation of scans performed into 3D models.

• ADVANTAGES 3D scanning allows: - high precision measurable surveys obtainable in much shorter times than traditional techniques to cope with the ever shorter time required by the market; - realistic simulations of future implants inserted in the existing department; - preventive analysis of interference for preparation of the area that will host the new plant; - quick checks on progress / completion of work to check correspondence between the work performed and the project to be followed; - findings faithful to reality that can be consulted over time with legal value.

• FIELDS OF USE The Leica P30 scanner allows multiple uses in the following sectors: Industrial applications - engineering - digital simulation - calculation of overall dimensions - plant engineering - verification and control Building-architectural applications - topographic surveys - elevations and building sections - volumes - civil construction Applications forensic - accident analysis - security plans.

TEAM

LORUSSO DONATO

AdministratorLORUSSO GIOVANI

Quality ManagerDRANCA TATIANA

Administration ManagerTCACI ION

Project ManagerPINZARU VADIM

EngineerJURA ANDREI

EngineerBUT PETRU

EngineerMUNTEAN SERGIU

EngineerGRIGORIEV EUGEN

EngineerCONTACT

str. Serghei Lazo 40

MD-2004 Chisinau

amministrazione@tfd.md

info@tfd.md

18

18